More olive oil at better quality

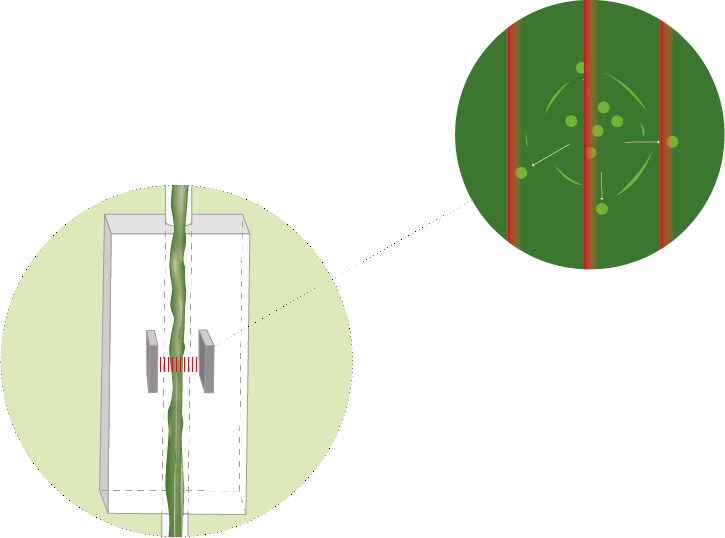

oliveCEPT® is a machine and technology that integrates into the traditional olive oil processing line to increase EVOO extraction and quality. Efficiency, maximum performance, and superior olive oil quality are improvements secured by oliveCEPT®.