Boosting cuttings for exceptional survival and rooting

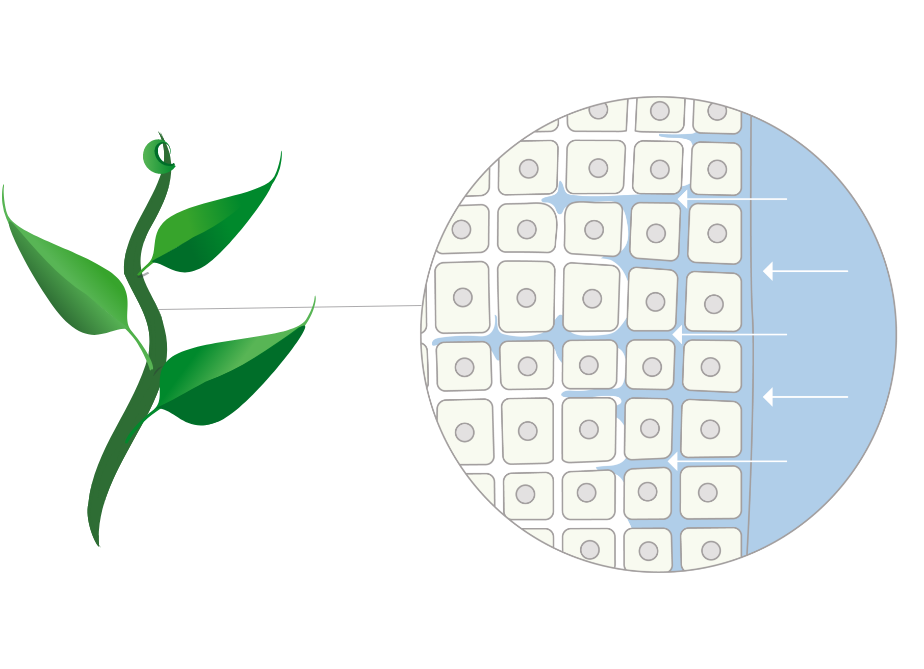

The OptiBoost vacuum impregnation (VI) technology improves the rooting and survival rate of cuttings. As well as decreases losses of eucalyptus and tropical clone cuttings. There are numerous benefits for the forest industry generated by the OptiBoost method. Including better rooting quality, a decrease in botrytis, acceleration of root formation, and an increase in the nurseries’ capacity.